SEWAGE TREATMENT PLANT

Nowadays the Sewage Treatment Plant (STP) became a statutory requirement of all State Pollution Control Boards, and everybody looking for an economical, easy-to-install, and operate compact type Sewage Treatment Plant. Since the land is extremely expensive, very few industries could afford the large treatment units recommended by most of the Consultants.

With the large demand and future requirements, we came up with the Portable Package Sewage Treatment Plant concept. It’s an FRP-coated MS fabricated unit that can be easily transported to the site which thus reduces the unnecessary civil cost, improves workmanship, speedy work, and excellent treated water quality. As per the client’s need and suitability, we offer the very latest technologies like MBBR, FAB, SAFF, SBR, and MBR.

Principle of Treatment:

It’s working on the principle of Aerobic Treatment with the help of aerobic bacteria, which is the most conventional and proven method throughout the world.

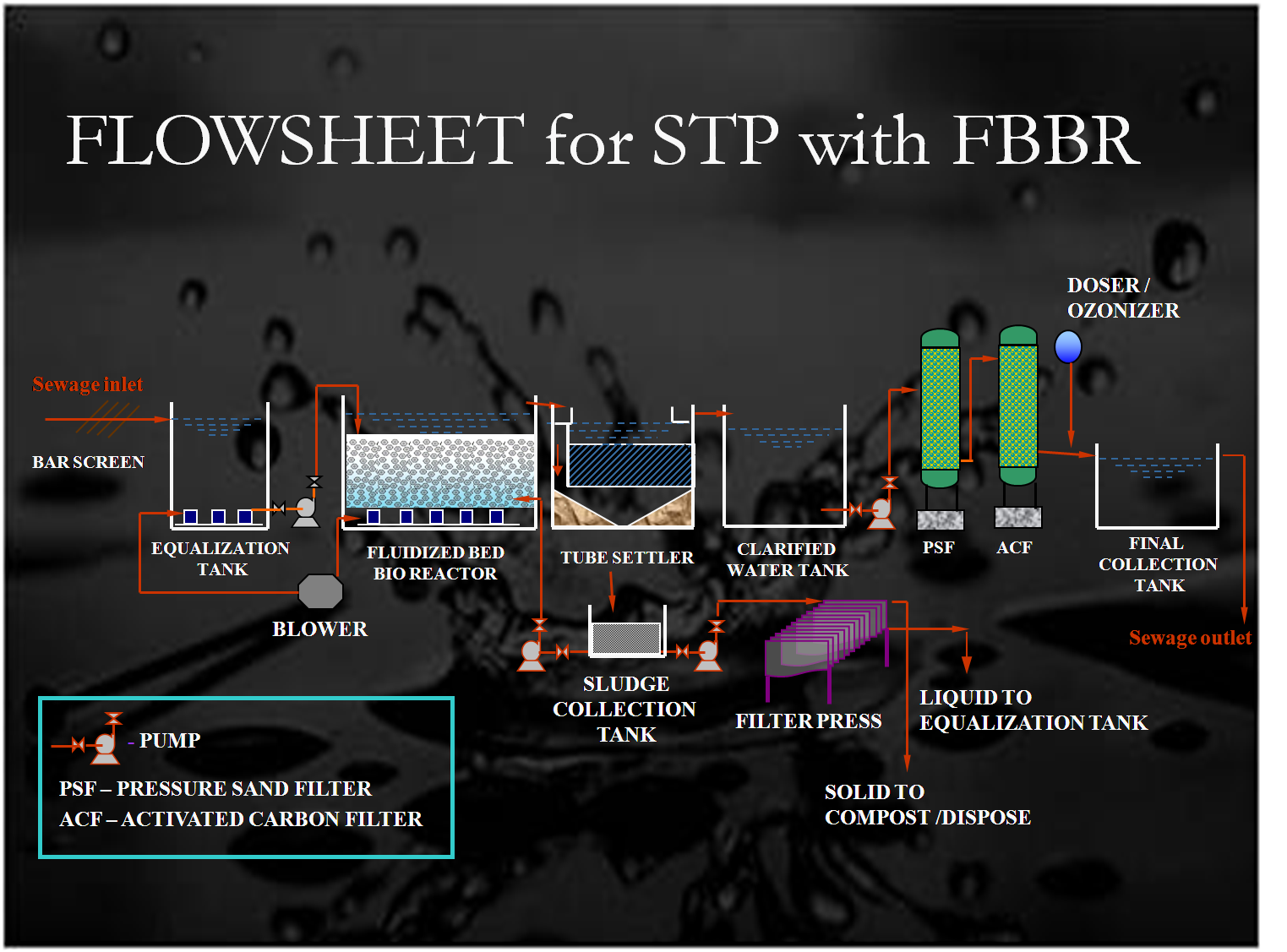

Treatment Steps:

- Equalization and Pre-Aeration.

- Bio-Reaction in the Aeration tank.

- Sedimentation.

- Filtration- Sand and Activated Charcoal

- Chlorination

- Sludge Drying and Disposal

- ASP- Activated Sludge Process

- MBBR- Mixed Bed Bio Reactor

- MBR- Membrane Bio Reactor

- SBR- Sequential Batch Reactor

- CSTP- Combined(Effluent)Sewage Treatment Plant

- SAFF- Submerged Aerobic Fixed Film

MBBR/FBBR Technology

MBBR which is commonly known as Moving Bed Biofilm Reactor is a modern water treatment technology and process. MBBR is a highly effective biological water treatment process that is based on a combination of biofilm media and conventional activated sludge processes.

The MBBR system consists of an aeration tank similar to that of an activated sludge tank. Plastic carriers (media) within the MBBR encourage the biological breakdown of the substrate in the influent wastewater. The media provide a protected surface area for aerobic and anaerobic bacterial communities, known as biofilm, to thrive. This additional surface area and the mixing of carriers due to the aeration system increases the contact between the biofilm and nutrients within wastewater, leading to higher levels of degradation and therefore increased productivity by the MBBR.

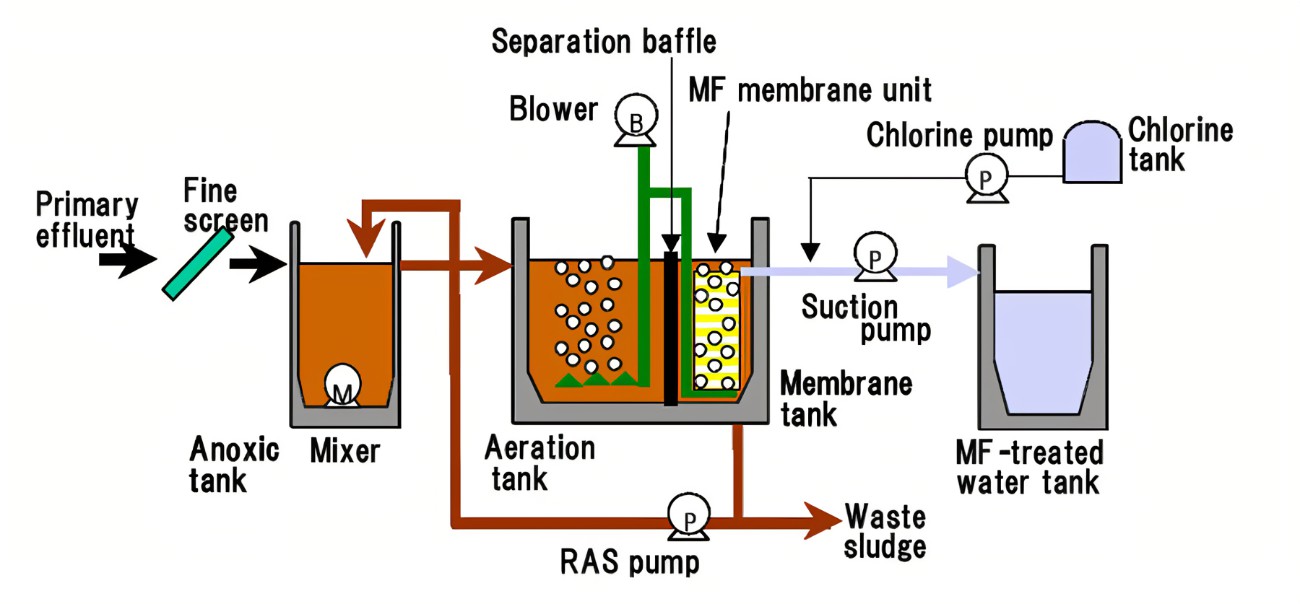

MBR Technology

The Membrane Bioreactor (MBR) is a combination of membrane separation and biological technology. Membrane Bioreactors (MBRs) combine conventional biological treatment (e.g. activated sludge) processes with membrane filtration to provide an advanced level of organic and suspended solids removal. It is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor that is now widely used for municipal and industrial wastewater treatment.