EFFLUENT TREATMENT PLANT

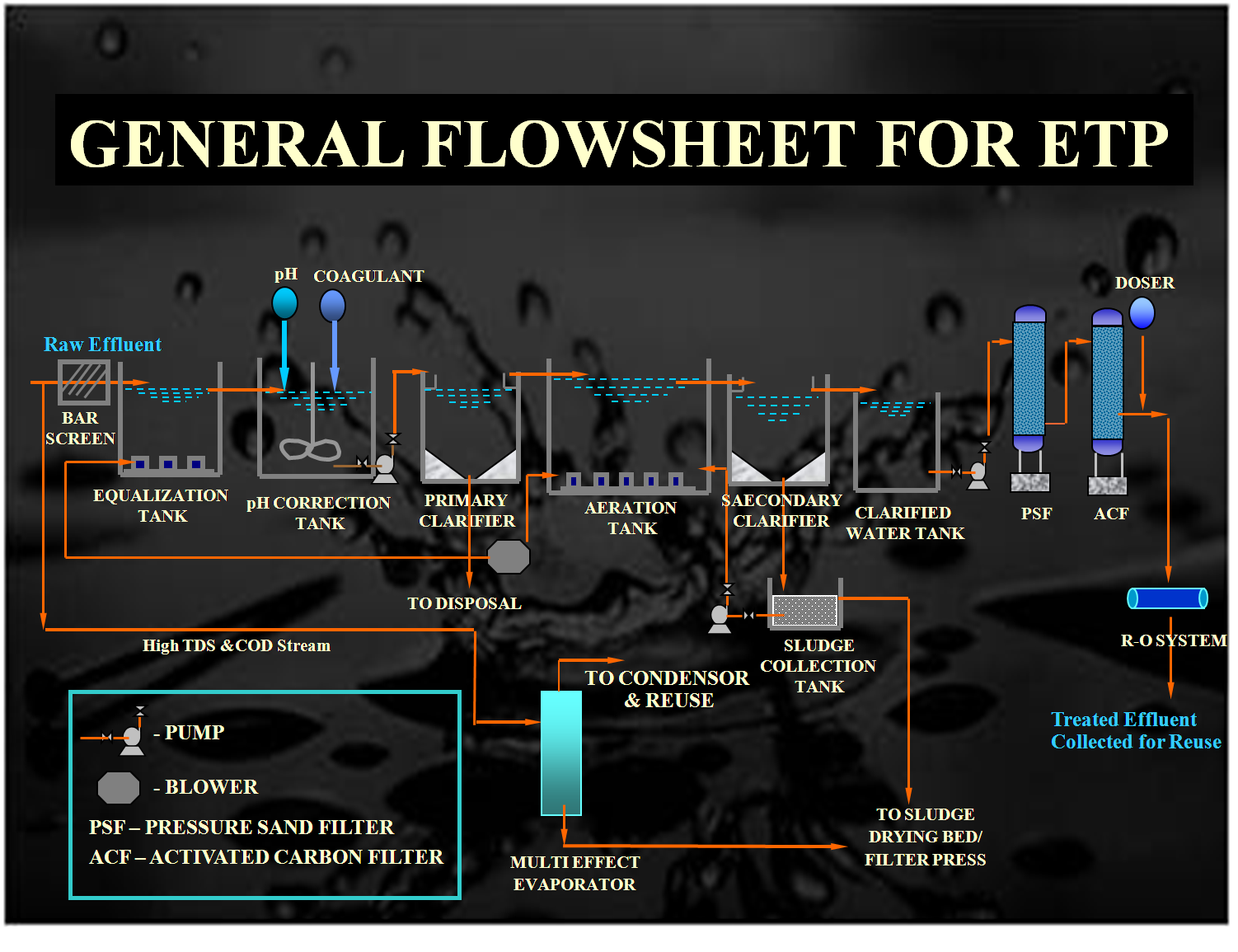

We Design, Manufacture, Supply, Erect, and Commission Effluent Treatment Plant (ETP) on a Turnkey basis for various types and natures of wastewaters, effluents that combines advanced Physico-chemical treatment, biological treatment processes with the tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids.

Our methodology – We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods to check techno-commercial Feasibility, and then designed treatment schemes, and processes accordingly to suit the purpose and need.

Our ETP systems are very compact, tailor-made designs, are portable required very less footprint to accommodate, and are energy efficient. The up-gradation and modification of the existing ETP system are possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).

We have Installed number of ETP in different sector

| Automotive industries | Glass Industries | Hotels |

| Food & Beverages industries | Textile & Garment Industries | Sheet Metal Industries |

| Dairy Industries | Plastic products | Dyeing Industries |

| Plating Industries | Pharmaceuticals | Pharmaceuticals |

| Electricals & Electronic goods | Hospitals | Tyre Manufacturing |

MSFRP Fabricated ETP installed at Fena Limited

Salient Features :

- Very cost effective: Less initial Investment.

- Types: Batch and Continuous.

- Atomization: Manual, Semi-automatic and Fully-automatic.

- Compact and proven design: Required very Low footprint.

- Quality Components and Mounting items: Special sludge pump and total corrosion-free UPVC piping & FRP/Epoxy Lined MS tanks.

- Water Recycle: Recycling of treated is possible with advanced treatment methodology like UF and RO.

- Operation and maintenance: Very silent in operation and any unskilled person can operate it, after proper training.

- Flexible design: Starting from 0.5 m3/day to 5000 m3/day capacities.

- Recurring Expenses: Economical plant operating costs, required regular treatment chemicals available in the market.